MECCANICA ALFONSINE

Medium-heavy carpentry

M.E.C. S.r.l

We are a manufacturer skilled to realize applications for any drilling machinery available on market: a qualified staff performs the assembly making use of high quality and high wear resistance materials and high mechanical resistance tubes for the rods.

All materials are provided with quality certificates and they are exclusively European source.

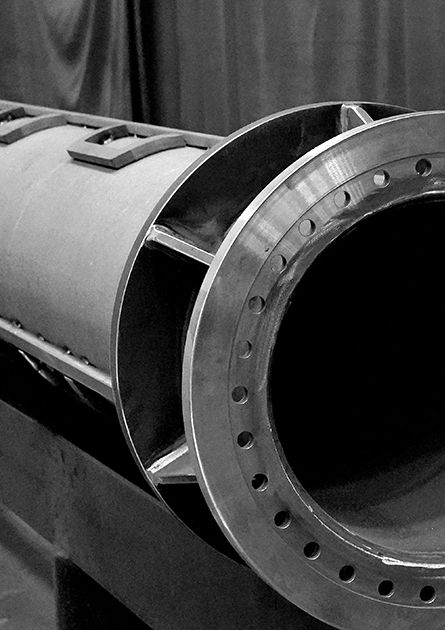

Kelly bar

Particularly, our factory is able to replace a worn out kelly bar from other brand with a new one, with the same features of the old one, perfectly interchangeable.

What is the difference between us and most kelly bar manufacturers?

It is the use of different materials in the different points where the various components are subjected to different mechanical and wear stresses.

Our telescopic drilling poles are particularly popular for the use in hard surfaces (rock) and for large torques (from 22,000 KnM onwards).

Kelly bar

We are a manufacturer skilled to realize applications for any drilling machinery available on market: a qualified staff performs the assembly making use of high quality and high wear resistance materials and high mechanical resistance tubes for the rods.

All materials are provided with quality certificates and they are exclusively European source.

The M.E.C. srl Meccanica Alfonsine kelly bars are designed by technicians and engineers with which is also possible to examine and realize specific solutions based on customer requests, or carry out feasibility studies for the adaptation of existing applications.Particularly, our factory is able to replace a worn out kelly bar from other brand with a new one, with the same features of the old one, perfectly interchangeable.

It is the use of different materials in the different points where the various components are subjected to different mechanical and wear stresses.

Our telescopic drilling poles are particularly popular for the use in hard surfaces (rock) and for large torques (from 22,000 KnM onwards).

Production

Spare parts and accessories kit

M.E.C. srl Meccanica Alfonsine is also a spare part and technical accessories supplier, for own manufacturing and upon request, such:

• swivel drilling winches;

• rubber shock absorbers (flanged rubber ring or mollingom circle for the lower, spring system for upper where applicable);

• drive stub to connect the drilling tool to bar

Products

PACKAGING

Kelly bar

several locking

elements

Accessories kit

Spare parts kit

Tecnici

qualified staff certificates

feasibility studies

M.E.C. srl Meccanica Alfonsine

48011 Alfonsine (RA)